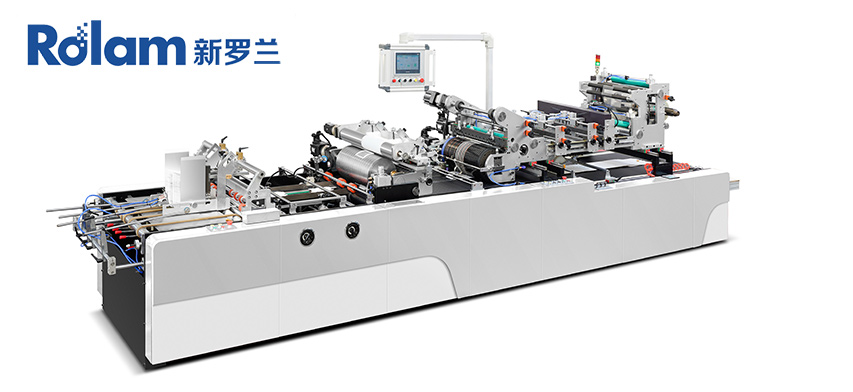

When Do You Need a Flute Laminating Machine?

Professionals in the packaging and printing industries often wonder exactly when to use a Flute Laminating Machine. It’s not a tool for every scenario—knowing its specific uses helps avoid wasted investments and ensures packaging meets practical needs. This article breaks down key situations where it becomes essential.

When Your Packaging Needs Both Strength and Print Quality

Corrugated paper is great for protecting products during transport and storage, but its rough surface makes high-quality printing difficult. Colors may look uneven, and fine details like logos or ingredient lists can blur.

A Flute Laminating Machine bonds smooth face paper like coated paper or art paper to corrugated. The result? Packaging keeps its strength to safeguard items, while the smooth layer enables sharp, vibrant prints. This works well for food packaging needing clear product info or cosmetic packaging needing a polished look.

When Packaging Must Resist Moisture and Damage

Moisture-sensitive products like pharmaceuticals, electronics, or fresh groceries need reliable protection. Plain corrugated paper absorbs water easily, weakening over time and risking damage to contents. Even small amounts of dampness can make it soft or prone to tearing.

A Flute Laminating Machine adds a moisture-resistant face paper to corrugated. This layer acts as a barrier, reducing water absorption and keeping packaging sturdy. It also guards against scratches during handling, ensuring intactness from production to delivery.

When You’re Packaging Heavy or Large Items

Heavy items like household appliances or industrial parts, plus large bulk goods, need packaging that bears weight without deforming. Plain corrugated paper often bends or breaks under constant pressure or repeated moving.

A Flute Laminating Machine enhances load-bearing capacity by adding strong face paper. The combined structure distributes weight evenly, preventing collapse. This is critical for shipping heavy-duty items where durability is non-negotiable.

When Brand Visual Consistency Is Required

Brands often want uniform packaging across product lines, like a beverage company wanting identical carton designs. Plain corrugated paper has an uneven texture, leading to inconsistent prints across different pieces.

A Flute Laminating Machine uses pre-printed smooth face paper that follows brand standards. This ensures every packaging piece looks the same, strengthening brand recognition and leaving a professional impression on customers.

Conclusion

A Flute Laminating Machine is a targeted solution—not a universal tool. It’s essential when you need to balance strength and print quality, resist moisture, support heavy items, or maintain brand consistency. Recognizing these scenarios helps you clearly decide if it fits your specific packaging needs.

If you want to explore equipment aligned with these scenarios and learn more about optimizing your workflow, visit our product page for detailed, tailored solutions.