Is a Folding Gluing Machine Suitable for Your Packaging Business?

Many packaging businesses wonder if a Folding Gluing Machine is a smart investment for streamlining production. With questions about fit, cost-effectiveness, and use, clarifying who benefits and what to consider is key. This article breaks down essentials to help you judge if it aligns with your operations.

Who Typically Needs a Folding Gluing Machine?

Its value depends on your production goals—here are the main groups that gain most:

Small to Medium-Sized Packaging Businesses

If your team folds/glues boxes by hand, a Folding Gluing Machine cuts manual hours. For businesses making 500–5,000 boxes daily, it eliminates handwork inconsistencies (uneven glue, misaligned folds) and frees staff for quality checks or order prep.

High-Volume Production Operations

For businesses making 10,000+ boxes daily, this machine is nearly essential. It keeps steady speed without losing precision—manual work or basic tools can’t match this. Over time, it also cuts labor costs by handling repetitive tasks better than a large team.

Businesses Needing Diverse Box Styles

If clients need diverse box types, a well-designed Folding Gluing Machine adapts. Unlike specialized manual tools that need retooling, many models let you switch designs with minimal adjustments, saving time and reducing errors.

What Factors Determine if It Fits Your Business?

Even if you fall into the groups above, check these critical factors:

Your Production Volume Consistency

A Folding Gluing Machine works best with steady production. If orders are sporadic (e.g., one large order every few months), it may sit idle, reducing cost-effectiveness. But consistent weekly/monthly output means it delivers ongoing value by keeping production on track.

The Complexity of Your Box Designs

The machine handles most standard box styles, but very complex designs (unusual folds, multiple glue points) may need specialized models. For simple to moderately complex boxes (standard shipping/product boxes), basic/mid-range machines work well. For highly custom designs, confirm the machine’s compatibility first.

The Materials You Use

Folding Gluing Machines work with paperboard, cardstock, and corrugated board—but not all handle every thickness. A machine for thin cardstock, for example, may struggle with thick corrugated. Match the machine’s material capacity to your regular stock (200-400 GSM cardstock, E/F-flute corrugated).

What Common Misconceptions Should You Avoid?

Clear these myths to avoid poor decisions:

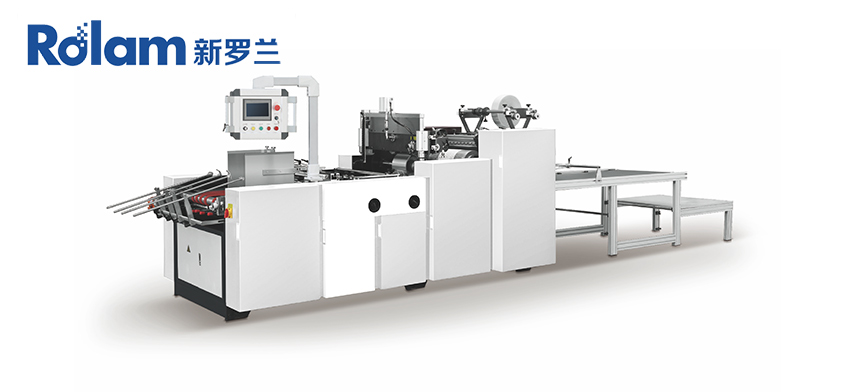

Myth 1: It’s Only for Large Corporations

Many small businesses think a Folding Gluing Machine is too big or costly. But compact, affordable models exist for small/medium operations—they take less space, have lower upfront costs, and let you cut manual work without scaling to enterprise size.

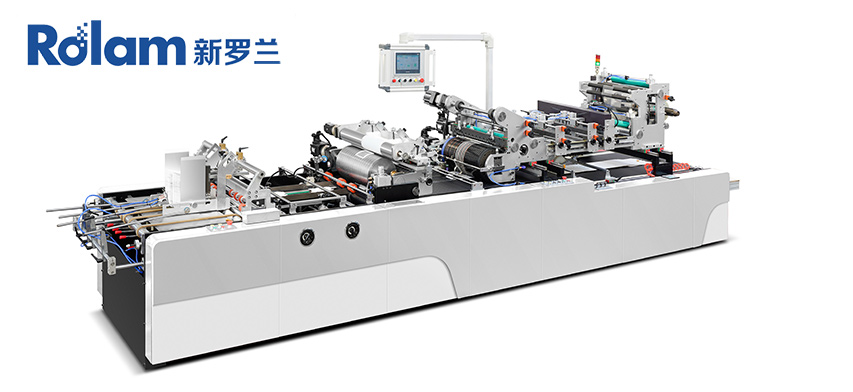

Myth 2: It’s Too Hard to Operate

Modern Folding Gluing Machines have user-friendly controls (touchscreens) and need minimal training. Operators learn basic setup/maintenance in a few days, and manufacturers often offer training support—no expert team needed.

Conclusion

A Folding Gluing Machine is valuable for consistent, efficient box production—but it’s not one-size-fits-all. To decide, check your production consistency, box design complexity, and material needs. With steady output, standard/moderately complex boxes, and common materials, it saves time, cuts errors, and lowers labor costs long-term.

To explore specific Folding Gluing Machine models tailored to small-batch, high-volume, or diverse-style production, visit our product page for detailed specifications matching different packaging operation needs.