How Do Film Laminators Work?

Many people rely on Film Laminators to protect or enhance paper products—from packaging boxes to printed materials—but few know the simple yet key steps that make lamination effective. If you've ever curious about what happens inside the machine to turn plain substrates into durable, glossy items, this guide explains the core workings clearly.

What Is a Film Laminator?

A Film Laminator is a machine designed to bond a thin plastic film (the "laminate") to a base material—usually paper, cardboard, or cardstock. This bond adds protection against moisture, tears, and wear, while also improving the material's appearance (like adding a glossy or matte finish). The process relies on three basic elements: heat, pressure, and cooling—to ensure the film adheres tightly and evenly.

Step 1: Preparing the Materials

Before lamination starts, two key materials need preparation: the base substrate (e.g., a cardboard sheet for packaging) and the laminating film.

First, the base material must be clean and flat. Any dust, dirt, or wrinkles on its surface will show through the film or prevent proper adhesion. Next, the laminating film—often made of polyethylene or polyester—is loaded onto the machine's unwinding rollers. The machine ensures the film feeds smoothly, without tangles, to match the speed of the base material.

Step 2: Heating and Pressurizing the Layers

This is the "bonding" step, where the film and base material come together.

The machine uses heated rollers (called "heat rollers") to warm the laminating film. The heat softens the film's adhesive layer (either pre-applied to the film or added by the machine). As the base material moves through the rollers, the softened film is pressed onto its surface with controlled pressure. The pressure ensures the film conforms to the base material's shape, eliminating air bubbles and creating a tight bond.

Importantly, the machine adjusts heat and pressure based on the material type—thicker cardboard, for example, may need slightly more heat to ensure the film sticks properly.

Step 3: Cooling to Set the Bond

After heating and pressing, the bonded material moves to a set of cooling rollers.

These rollers are at room temperature (or slightly cooled) and work to "set" the bond. Cooling the material quickly prevents the film from peeling or warping as it exits the machine. It also ensures the bond stays strong over time, even when the laminated product is handled or exposed to minor temperature changes.

Step 4: Trimming (If Required)

Some Film Laminators include a trimming function for final touches.

If the laminating film is wider than the base material, the machine's built-in trimmers cut away the excess film along the edges. This step gives the finished product a clean, professional look—critical for items like packaging boxes or marketing materials where appearance matters. Not all machines have this feature, but it's a common add-on for applications that need precise finishing.

Conclusion

Knowing how a Film Laminator works helps you make better choices: whether you're selecting a machine for your business or troubleshooting minor issues (like air bubbles, which often stem from uneven heat or dirty materials). It also lets you appreciate how each step contributes to the final product's durability and appearance.

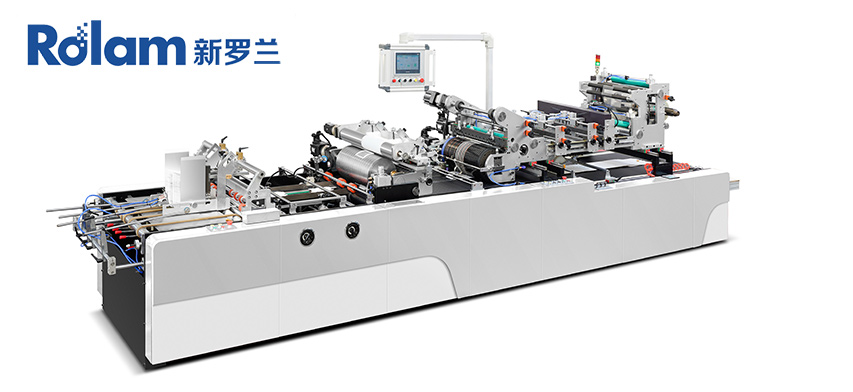

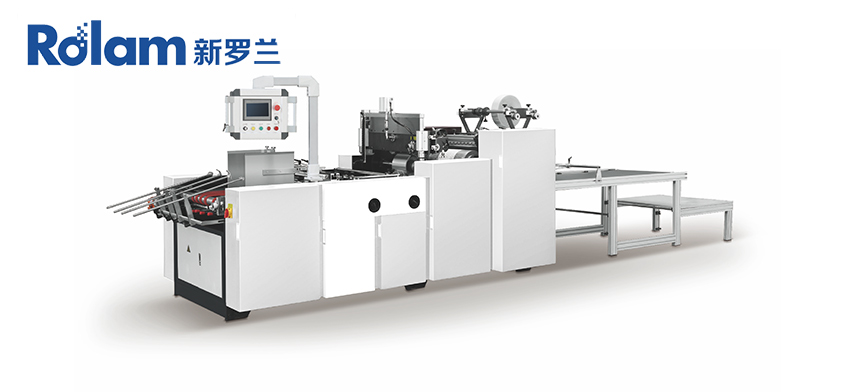

If you're looking for a Film Laminator that follows these reliable processes to deliver consistent, high-quality results—whether for packaging, printing, or other applications—you can explore our product range on our website's dedicated Film Laminator page. There, you'll find machines designed to handle different material types and production needs, built to maintain the core steps that make lamination effective.