How Can Smart Automation Transform the Future of Carton Folding and Gluing?

The packaging industry is evolving fast. As production lines demand higher speed, accuracy, and consistency, smart automation has become the driving force in modern carton folding and gluing. This transformation is not only about faster machines—it’s about intelligent coordination, stable performance, and long-term efficiency in every process.

Smarter Folding and Gluing: What It Really Means

In the past, folding and gluing relied heavily on manual adjustments. Operators needed to control alignment, glue application, and carton positioning step by step.

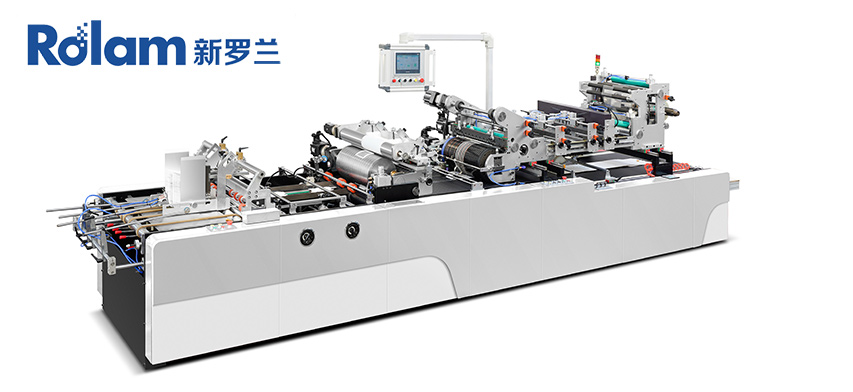

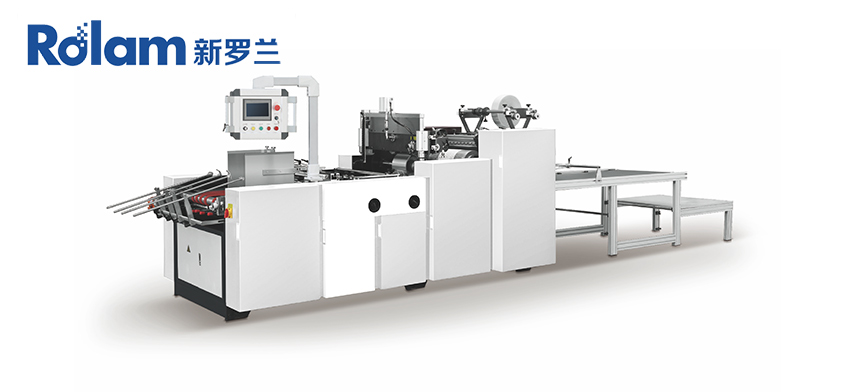

Now, automated folder gluer systems integrate PLC control, servo-driven motors, and photoelectric sensors to manage these tasks precisely. The result is real-time correction and steady production without frequent manual interference. Such systems help manufacturers save time, reduce waste, and ensure every carton meets strict quality standards.

The Benefits That Matter to Packaging Manufacturers

The shift to automation in folding and gluing offers several practical advantages:

- Accurate folding and gluing — Advanced servo systems maintain consistent positioning and gluing precision.

- Faster setup and adjustment — Machines with quick changeover systems reduce downtime between orders.

- Flexible operation — Operators can easily switch between box styles such as straight-line, crash-lock, or 4 & 6 corner designs.

- Energy-saving performance — Efficient motors and intelligent glue control systems minimize resource consumption.

These advantages make automated folder gluer machines essential for factories aiming to maintain productivity and consistent quality at scale.

How Automation Supports Sustainable Production

Sustainability is an integral goal in packaging manufacturing. Automated folding and gluing reduce waste by minimizing misalignment and optimizing glue application.

By controlling pressure, timing, and adhesive flow through intelligent PLC systems, manufacturers achieve lower material loss and more stable performance.

This balance between speed and precision not only improves efficiency but also supports eco-conscious production practices.

The Future of Packaging Machinery

Modern folder gluer machines are increasingly adopting modular, digital, and data-assisted designs.

While full AI integration remains a developing field, today’s systems already include features such as touch-screen interfaces, digital calibration, and automatic fault detection.

These advancements signal a clear trend: the packaging industry is moving toward machines that think, adjust, and operate with minimal manual input—an achievable step powered by automation, not speculation.

Conclusion

Smart automation is redefining the way cartons are folded and glued.

It ensures precision, flexibility, and sustainability—qualities that every manufacturer needs to stay competitive in a fast-changing market.

By investing in reliable automated technology, packaging producers can secure efficiency today and adaptability for tomorrow.

Take the Next Step

To explore advanced folding and gluing systems designed with intelligent automation and high production reliability, visit the Folder Gluer Machine section on GaokeMachine for detailed technical information and tailored solutions.