How to Pick the Right Window Patching Machine for Your Packaging?

Windowed cartons are essential for showcasing products in food, cosmetics, and pharmaceutical industries—but choosing a suitable window patching machine can be confusing. This article breaks down key points to help you make the right choice, based on practical packaging needs.

How Does a Window Patching Machine Adapt to Different Packaging Materials?

Your packaging material (carton board or corrugated paper) directly affects which machine works for you—mismatched machines cause jams or damage.

Adapting to Carton Board

Carton board is common for light products like cosmetics or stationery. Look for machines with servo-driven paper feeding: this gentle, consistent system prevents tears, while touchscreen controls let you adjust feeding lengths quickly—perfect for small-batch or custom cartons.

Handling Corrugated Paper

Corrugated paper is thicker for heavy packaging (e.g., industrial goods). Opt for machines with intermittent belt feeding (that runs without stopping) to move stiff sheets smoothly. PLC control adds precision, avoiding jams that slow production.

What Efficiency Features Matter for a Window Patching Machine?

Efficiency keeps your packaging line on track—focus on features that cut downtime and boost output.

Continuous Paper Feeding

Machines with non-stop paper feeding (like models designed for high-volume runs) eliminate pauses between sheets. This is critical if you produce large batches of windowed cartons, as it reduces total production time without sacrificing quality.

Consistent Speed Control

Look for machines with reliable speed regulation (often from trusted components like servo drives). Consistent speed ensures every window is aligned correctly—no misprints or uneven patches, which saves time on rework.

How Does User-Friendliness Impact Your Window Patching Machine Choice?

A machine that’s easy to operate reduces training time and human error—key for smooth daily use.

Intuitive Touchscreen Interfaces

Machines with touchscreen controls let operators input settings (like feeding length) in seconds. No complex manuals are needed, so new staff can learn quickly, and adjustments for different carton sizes are hassle-free.

Simple Maintenance Access

Choose machines designed for easy maintenance (e.g., accessible parts). This means your team can perform basic checks or minor fixes without waiting for technicians—keeping the machine running longer.

Conclusion

To pick the right window patching machine, focus on three core points: material adaptability (for carton board or corrugated paper), efficiency features (continuous feeding, consistent speed), and user-friendliness (touchscreens, easy maintenance). These ensure the machine fits your packaging line and works reliably.

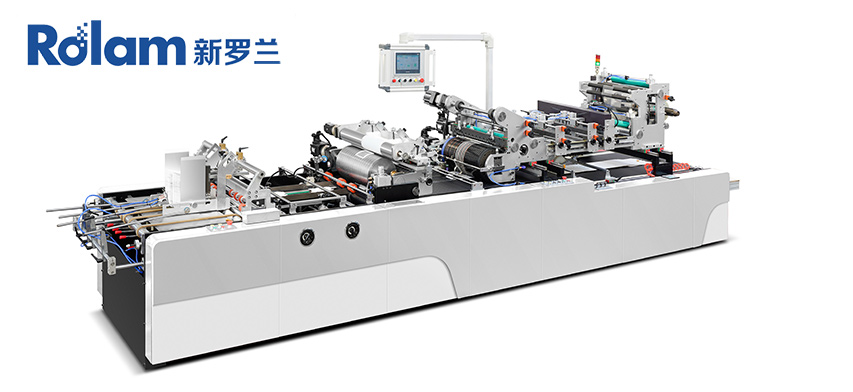

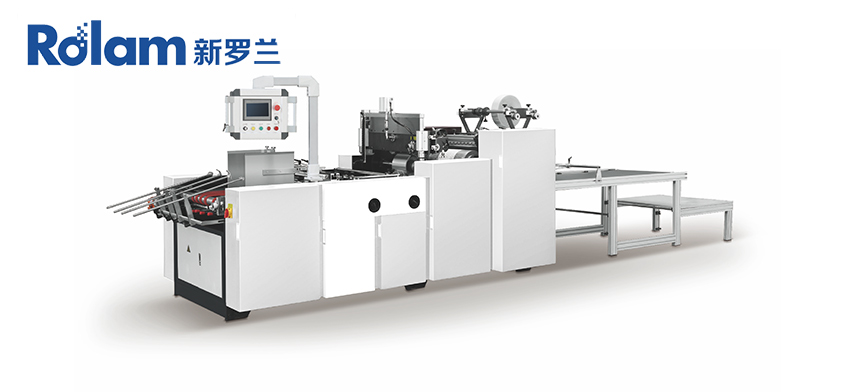

If you’re looking for window patching machines that meet these criteria—whether for small-batch cosmetic cartons or large-volume corrugated packaging—visit our product page. You’ll find detailed models (such as the TC series) tailored to different packaging needs.