Understanding the folder-gluer process: How to turn flat sheets into finished cartons

What is the process of folder gluer?

Folder-gluers are key pieces of equipment in the packaging industry, converting die-cut flat sheets into ready-to-use cartons that can be folded and glued. From food and pharmaceuticals to cosmetics and electronics, folder-gluers are able to produce a wide range of cartons efficiently and at high speeds.

This article will detail the detailed process of folder-gluers, their key components, and how advanced equipment like the Gaoke LC Series Fully Automatic Folder-gluers can improve production efficiency.

I.Folder-gluer detailed process

1. Feeding and alignment

Flat sheets (pre-cut and creased) are fed into the machine by manual or automatic feeders.

Sensors and guides ensure precise alignment to avoid folding errors or mis-application of glue.

2. Folding and gluing

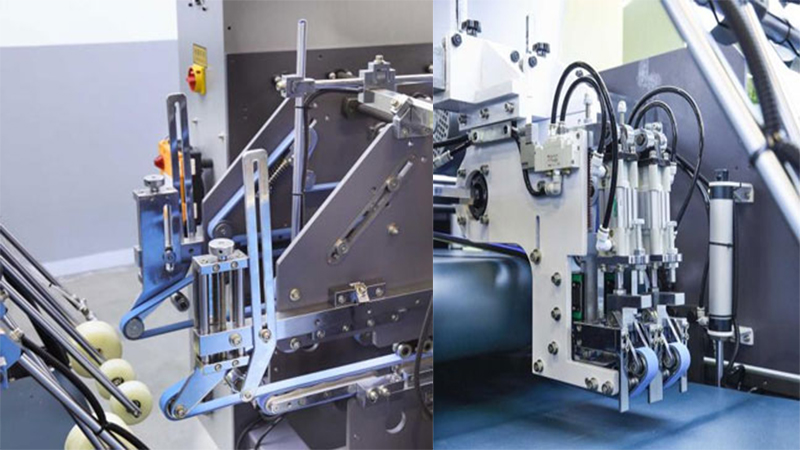

The machine uses mechanical folding plates, belts and rollers to fold cartons along pre-scored creases.

Glue is applied at critical points (side seams, seals or locks) by precision nozzles or rollers.

Specialized folding units handle complex designs, such as bottom-lock boxes or 4/6-corner boxes.

3. Flap (for multi-sided cartons)

Some cartons require a 90° rotation for additional folds (e.g. fold-over closure).

Integrated flap system repositions the cartons without manual intervention.

4. Compression and drying

The folded cartons pass through a compression belt to ensure a secure bond.

Depending on the type of glue (hot melt or PVA), drying can be natural or with the aid of airflow.

5. Output and stacking

After the finished cartons leave the machine, they are stacked for packaging or further processing.

Optional automatic counter and stacker increase efficiency at the end of the line.

II.Key components of a modern folder-gluer

1. Paper feeding system – ensures smooth paper feeding (high-speed models are equipped with a vacuum feeder).

2. Folding unit – with adjustable baffles and rollers for different carton formats.

3. Gluing system – precision glue applicator to minimize waste and achieve strong bonding.

4. Collision and flip mechanism – can handle cartons with complex shapes (e.g., medicine or cosmetic boxes).

5. Control panel – touch screen interface for fast task switching and real-time adjustments.

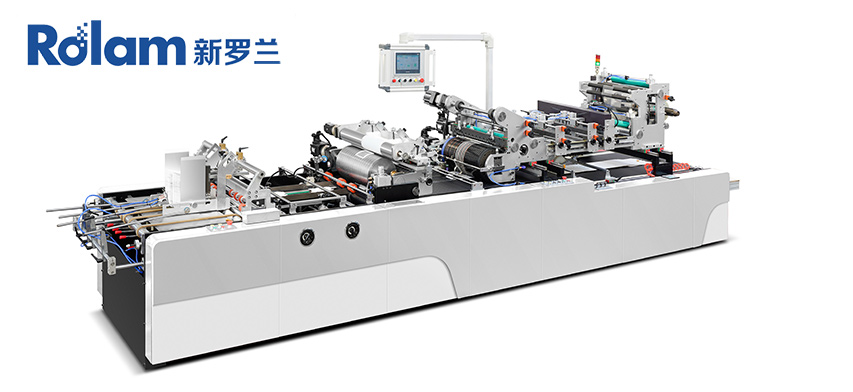

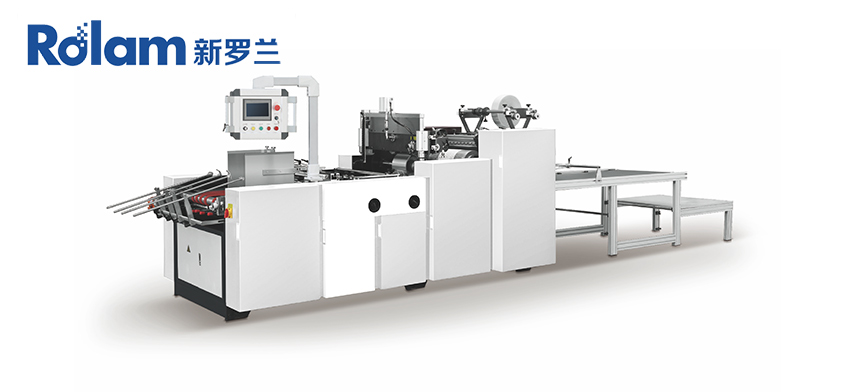

III.Why choose Gaoke LC series automatic folder gluer?

As a professional folding gluing machine manufacturer, Gaoke is committed to providing customers with customized folder glue solutions to optimize packaging processes, improve production efficiency and processing accuracy. Its LC series products have significantly improved the level of traditional processes through a number of innovative designs:

Ultra-fast switching – minimize downtime between jobs.

Multi-box compatibility – can handle straight boxes, bottom-lock boxes and 4/6 corner cartons.

Integrated 90° rotation function – no manual repositioning required.

Heavy-duty structure – designed for all-weather production in harsh environments.

Conclusion

Gaotech combines the precision mechanics of folder-gluers with the intelligent automation to transform flat sheets of paper into market-ready cartons in seconds. With advanced technologies such as the Gaotech LC series, manufacturers can improve speed, flexibility and reliability, and achieve efficient production with superior equipment.

If you are still wasting precious time due to cumbersome processes and equipment that often fails, Gaoke will provide you with an efficient and simple fully automatic folder-gluer!