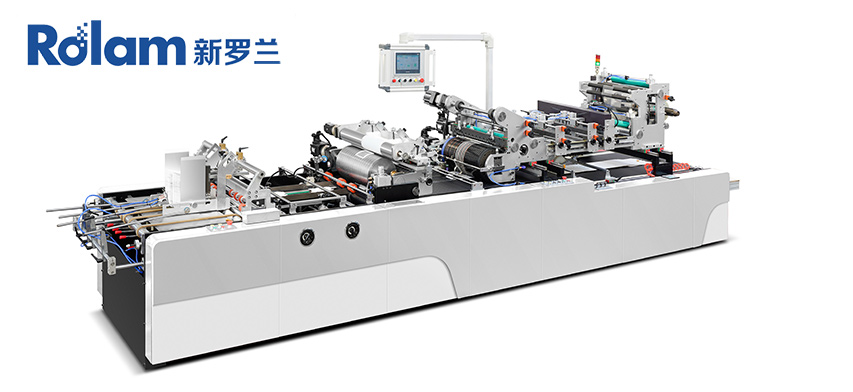

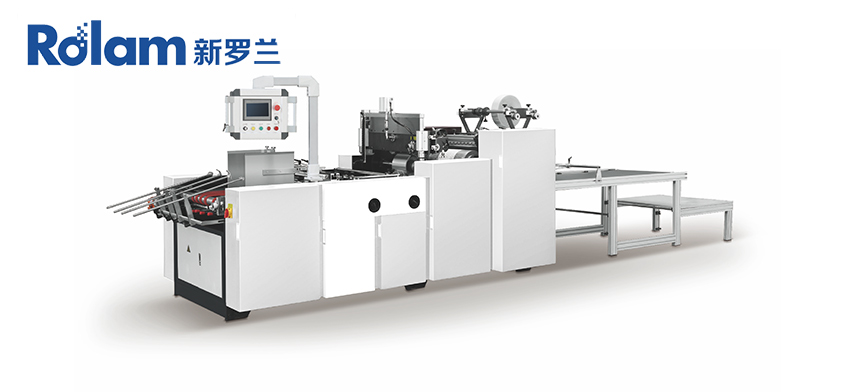

How Folder Gluers Work

Folder gluers are essential machines in modern packaging production that transform flat materials into finished boxes, cartons, and other folded products. These machines efficiently fold the material along pre-punched perforations and apply glue to secure the structure. But how do they work exactly? What industries rely on them? Let's explore the working principles and applications of folder gluers.

How does a folder gluer work?

Folder gluers automate the folding and gluing process with precision and speed. Here's a step-by-step explanation of how it works:

1. Feeding

Flat material (usually corrugated board, paperboard, or folding cartons) is fed into the machine via a manual or automatic feeder.

2. Pre-folding (optional)

Some machines include a pre-folding step that creases the material along the perforations, ensuring neat and accurate folding for subsequent processes.

3. Gluing

The gluing unit applies adhesive to the specific cover or panel that needs to be glued. Hot melt, cold glue, or PVA adhesives are usually used.

4. Folding Material

The machine folds the paper into the desired shape (e.g., cartons or boxes) along pre-scored lines. Different folding mechanisms (e.g., belt folders, buckle folders, or folding knives) ensure precise alignment.

5. Lamination and Securing

Lamination belts or rollers hold the folded material in place while the glue cures, ensuring a secure bond.

6. Output and Stacking

The finished product is transported to a conveyor or stacking system, ready for further processing or packaging.

A folder gluer automates the process of folding and gluing packaging materials like cardboard or paperboard into finished boxes. The machine first feeds flat sheets, then precisely folds them along pre-scored lines while applying glue to specific flaps. Pressure rollers secure the folds as the adhesive sets, and the finished boxes are stacked for output. This streamlined process ensures high-speed, consistent production of cartons, displays, and other packaging solutions.

Materials Processed by Folder-Gluers

Folder-Gluers can process a wide variety of materials, including:

Corrugated board – used for shipping boxes and retail packaging.

Folding board – commonly used for food, cosmetics, and pharmaceutical packaging.

Solid bleached sulfate (SBS) board – ideal for high-end packaging.

Micro-corrugated and other lightweight boards – used for retail displays and protective packaging.

Industries Using Folder-Gluers

While folder-gluers have a wide range of uses, they are primarily used in:

Packaging manufacturing – producing cartons, boxes, and display racks.

Food & Beverage – Making cereal boxes, pizza boxes and beverage trays.

Pharmaceutical – Folding medicine boxes and cosmetic packaging.

E-commerce & Shipping – Making durable corrugated boxes for shipping.

Benefits of using a folder-gluer

High-speed production – Processing thousands of units per hour.

Precise and consistent – Ensures uniform folding and gluing for high-quality packaging.

Reduced labor costs – Automation minimizes manual folding and gluing.

Versatility – Adjustable to different carton styles and sizes.

Conclusion

Folder-gluers are essential equipment for the packaging industry, streamlining the production of cartons and boxes with speed and precision. By automating the folding and gluing process, folder-gluers increase efficiency while maintaining high quality standards. Whether it’s e-commerce, food packaging or pharmaceuticals, folder-gluers play a vital role in modern manufacturing.