How do folder gluers efficiently produce complex box structures?

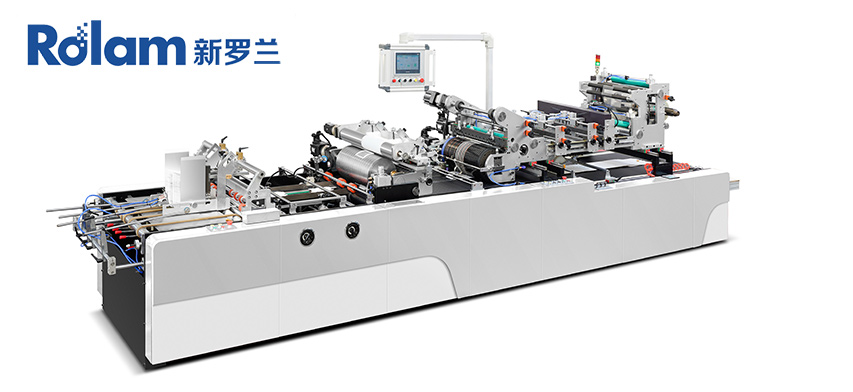

The paperboard packaging industry continues to develop, and there is a growing demand for complex box structures, such as lock-bottom boxes, automatic bottom-sealing cartons, and specialty packaging. To efficiently meet these demands, manufacturers rely on advanced cardboard box gluers, especially fully automatic high-speed intelligent folder gluers.

I. The role of folder gluers in complex box manufacturing

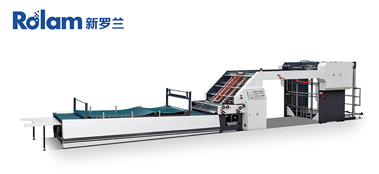

Folder gluers efficiently produce complex box structures by using automated systems with precise folding, gluing, and drying mechanisms to assemble pre-cut cardboard into intricate designs.

Lock bottom boxes – These self-locking designs do not require additional adhesives, which increases assembly speed.

Automatic bottom sealing cartons – These cartons are often used for retail and automatically form a solid bottom when opened.

Specialty boxes – Custom-shaped boxes (e.g., display boxes, luxury packaging) require extremely high folding and gluing precision.

Traditional manual or semi-automatic machines struggle with these designs, but fully automatic high-speed intelligent folder gluers can handle them efficiently.

II. Main features of fully automatic high-speed intelligent folder gluers

To mass-produce complex box structures, modern folder gluers use the following technologies:

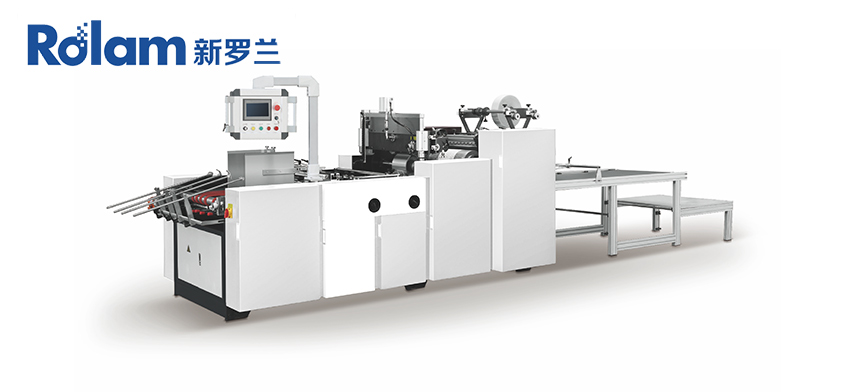

1. Precision folding mechanism

Adjustable folding tools to accommodate different box types (e.g., lock-edge boxes, four-corner boxes, and six-corner boxes).

Laser-guided alignment to ensure accurate positioning of the box lid for consistent quality.

2. Advanced glue application system

Hot melt or cold glue applicators to provide a strong, fast-curing bond.

Non-contact glue spraying to reduce waste and improve precision of complex designs.

3. High-speed automation

Robotic feeding and unloading minimizes manual operations and increases productivity (up to *600+ cartons per minute*).

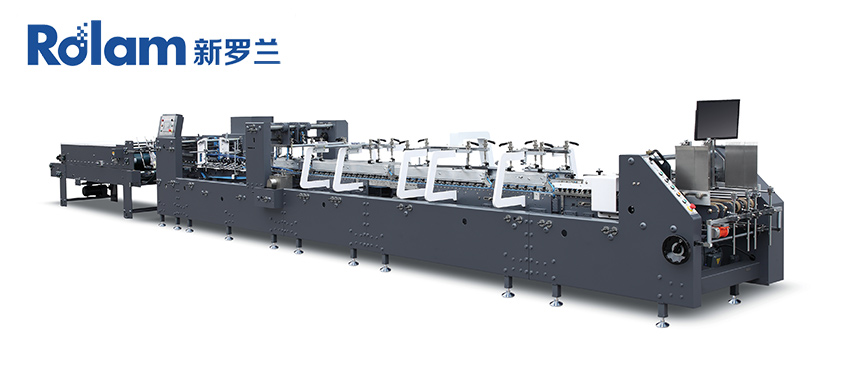

Inline quality inspection (e.g., vision system) detects misalignment or glue defects in real time.

4. Smart Adjustment and Fast Changeover

Pre-programmed settings allow for quick switching of carton styles.

Self-learning artificial intelligence optimizes machine performance for different materials (e.g. corrugated, cardboard).

Gaoke is an intelligent manufacturer with more than 20 years of industry experience, focusing on providing automation equipment and customized solutions for printing, packaging and post-processing. With a deep understanding of a variety of materials such as corrugated paper and cardboard, we are able to design efficient and precise automation machinery for different production needs, covering key process links such as printing, die-cutting, and molding, helping customers improve production efficiency and optimize costs.

III. Advantages of using smart folder gluers to produce complex cartons

| Features | Benefits |

| High-speed production | Shortened lead times, ideal for large orders |

| Minimize glue waste | Reduce material costs and environmental impact |

| Reduce reliance on labor | Reduce operating costs and human errors |

| Consistent quality | Ensure uniform folding and gluing for premium packaging |

| Flexible customization | Process multiple carton styles without downtime |

Summary

For manufacturers of lock-bottom cartons, auto-bottom cartons and specialty cartons, investing in fully automatic high-speed smart folder gluers will be a game-changer. With unparalleled efficiency, precision and adaptability, these machines are an integral part of modern cardboard packaging.