Understanding Flute Laminator Machines: Types and Applications

As the packaging industry develops towards efficiency and intelligence, laminating technology is also constantly innovating. From traditional manual laminating to fully automatic servo drive, from basic bonding to intelligent temperature control monitoring, different types of laminating machines such as servo laminating machines, intelligent laminating machines, manual laminating machines, and fully automatic corrugated laminating machines Gaoke provides a variety of choices for companies of different sizes.

What is a Flute Laminator Machine

A flute laminator machine is a specialized piece of equipment used in the corrugated packaging industry to bond layers of corrugated board (flutes) with liners or other materials. This process enhances the strength, rigidity, and printability of packaging materials, making them suitable for high-end boxes, displays, and protective packaging solutions.

Flute laminators apply adhesives (such as water-based glue or hot melt) to corrugated sheets before pressing them together under controlled pressure and heat. The result is a multi-layered, durable board that can withstand heavy loads, moisture, and rough handling.

Depending on production needs, different types of flute laminators are available, including Servo Laminating Machines, Intelligent Laminating Machines, Manual Laminating Machines, and Automatic Flute Laminating Machines. Each type offers unique features tailored to various manufacturing requirements.

Types of Flute Laminator Machines

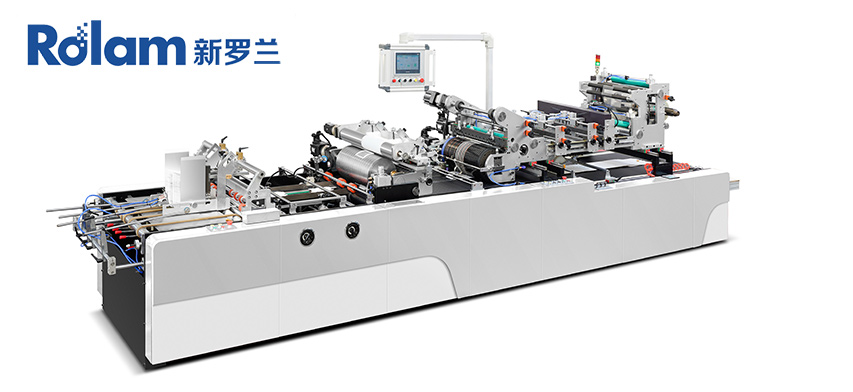

1. Servo Laminating Machine

A Servo Laminating Machine utilizes advanced servo motors for precise control over speed and tension, ensuring consistent adhesive application and smooth lamination. These machines are highly efficient, reducing material waste and improving production accuracy.

Key Features:

High-speed operation with servo-driven mechanisms

Precise glue application for uniform bonding

Energy-efficient and low maintenance

Ideal for medium to large-scale production

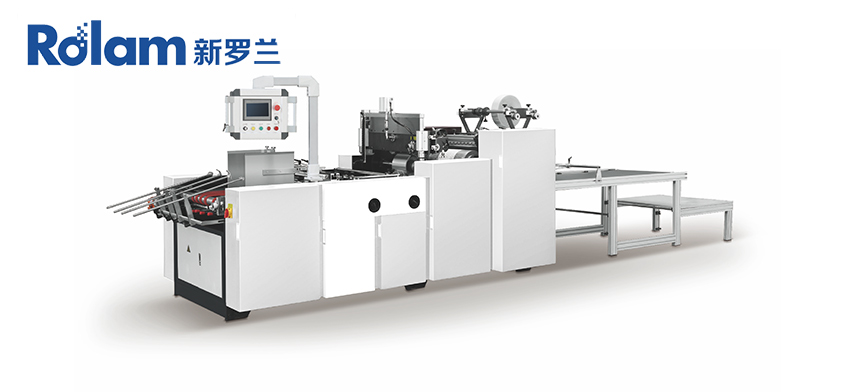

2. Intelligent Laminating Machine

An Intelligent Laminating Machine incorporates automation and smart technology to optimize the lamination process. These machines often feature touch-screen controls, automatic glue dispensing, and real-time monitoring for enhanced productivity.

Key Features:

Automated adjustments for different material thicknesses

Digital control panel for easy operation

Self-diagnostic systems for troubleshooting

Reduced manual intervention, improving efficiency

3. Manual Laminating Machine

A Manual Laminating Machine is a cost-effective solution for small-scale operations or businesses with low production volumes. These machines require operator involvement for feeding and alignment but are simple to use and maintain.

Key Features:

Affordable and easy to operate

Suitable for small workshops or custom packaging needs

Minimal setup time

Requires manual adjustment for different materials

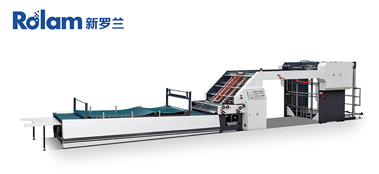

4. Automatic Flute Laminating Machine

An Automatic Flute Laminating Machine is designed for high-volume production, featuring full automation from feeding to stacking. These machines significantly reduce labor costs while ensuring consistent quality.

Key Features:

Fully automated operation with minimal human intervention

High-speed production with precision lamination

Compatible with various adhesives (water-based, hot melt, etc.)

Integrated drying and cooling systems for faster processing

Applications of Flute Laminator Machines

Flute laminators are widely used in industries requiring high-quality packaging, including:

Food & Beverage Packaging – Enhances moisture resistance and durability.

Electronics Packaging – Provides cushioning and protection for fragile items.

Pharmaceutical Packaging – Ensures tamper-proof and sturdy boxes.

Retail & Display Boxes – Improves printability for branded packaging.

Conclusion

Choosing the right flute laminator machine depends on production scale, automation needs, and budget. Servo and Intelligent Laminating Machines offer precision and smart controls, while Manual Laminating Machines are ideal for small businesses. For large-scale operations, an Automatic Flute Laminating Machine ensures efficiency and consistency.

Investing in the right laminating technology can significantly enhance packaging quality, reduce waste, and improve overall productivity in the corrugated packaging industry.