Understanding the Differences Between Folder Gluers and Flexographic Folder Gluers

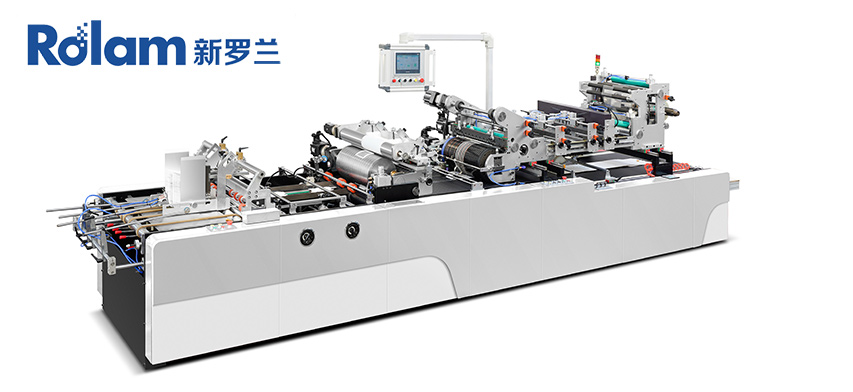

In the packaging and printing industry, folder gluer machine play a crucial role in converting flat sheets into folded and glued cartons. However, not all folder gluers are the same. Two common types are standard folder gluers and flexographic folder gluers, each serving distinct purposes in production.

This article explores the key differences between these machines, their functionalities, and their applications to help businesses choose the right solution for their packaging needs.

What Is a Folder Gluer Machine?

A folder gluer machine is a specialized piece of equipment used in the packaging industry to fold and glue paperboard or corrugated sheets into boxes, cartons, and other packaging structures. These machines streamline production by automating the folding and gluing process, ensuring precision and efficiency.

Key Features of Standard Folder Gluers:

Designed for folding and gluing pre-printed or plain carton blanks.

Uses mechanical folding plates, belts, and glue application systems.

Ideal for high-speed production of standard packaging like shipping boxes, food cartons, and retail packaging.

Typically requires pre-printed materials before folding.

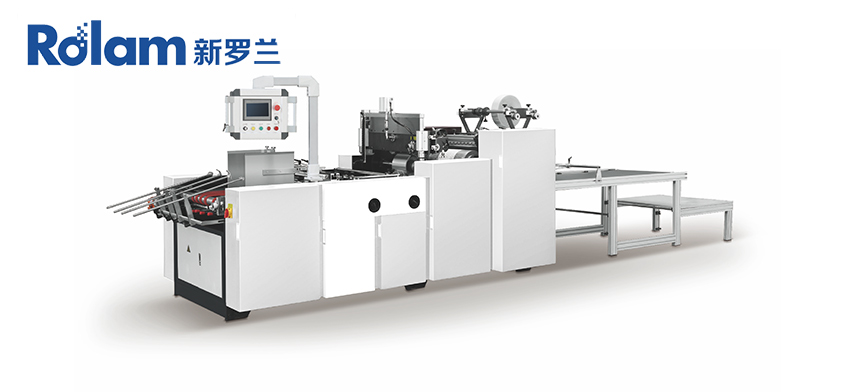

What Is a Flexographic Folder Gluer?

A flexographic folder gluer (often called a flexo-folder-gluer) combines flexographic printing with folding and gluing in a single machine. Unlike standard folder gluers, which only fold and glue pre-printed sheets, flexo-folder-gluers can print, fold, and glue in one continuous process.

Key Features of Flexographic Folder Gluers:

Integrates flexographic printing for inline printing of designs, text, or barcodes.

Eliminates the need for pre-printed materials, reducing production steps.

Suitable for short to medium runs where customization is required.

Often used for *corrugated boxes*, retail displays, and branded packaging.

Key Differences Between Folder Gluers and Flexographic Folder Gluers

| Feature | Standard Folder Gluer | Flexographic Folder Gluer |

| Printing Capability | No printing—requires pre-printed blanks | Inline flexographic printing |

| Production Flexibility | Best for high-volume, standardized packaging | Ideal for short to medium runs with variable designs |

| Setup Time | Faster setup for folding/gluing only | Longer setup due to printing adjustments |

| Cost Efficiency | Lower initial cost, but pre-printing adds expense | Higher initial cost but reduces pre-printing costs |

| Applications | Shipping boxes, food packaging, pharmaceutical cartons | Custom-printed corrugated boxes, retail packaging, promotional displays |

Which One Should You Choose?

The choice between a standard *folder gluer machine* and a flexographic folder gluer depends on your production needs:

Choose a standard folder gluer if:

You use pre-printed materials.

You need high-speed production of uniform packaging.

Your designs remain consistent with minimal variation.

Choose a flexographic folder gluer if:

You require printing customization (logos, barcodes, variable data).

You produce short to medium runs with frequent design changes.

You want to reduce dependency on pre-printed stock.

Conclusion

Both folder gluers and flexographic folder gluers are essential in packaging production, but they serve different purposes. Standard folder gluers excel in high-speed folding and gluing, while flexo-folder-gluers offer the added benefit of inline printing for customized packaging solutions.

By understanding these differences, businesses can invest in the right machinery to optimize efficiency, reduce costs, and meet their packaging demands effectively.

Would you like recommendations on specific brands or models of folder gluer machines? Let us know in the comments!