What Are the Key Components and Features of Folder Gluers?

Folder gluers are vital machines in the packaging and printing industries, designed to efficiently fold and glue paperboard or corrugated materials into boxes, cartons, and other packaging solutions. But what exactly makes up a folder gluer, and what features should you look for when choosing one?

In this article, we’ll break down the essential components and standout features of folder gluers, helping you understand how they work and what to consider before investing in one.

What Are the Main Components of a Folder Gluer?

1. Feeding Section – Where Does the Process Begin?

The feeding section is where flat sheets are loaded into the machine. A smooth and consistent feed is crucial to avoid jams. Common feeding mechanisms include:

Suction Feeders – Use vacuum suction to pick up sheets accurately.

Pile Feeders – Ideal for high-speed operations with stacked sheets.

2. Pre-Folding Unit – Why Is It Important?

Before the main folding process, some machines include a pre-folding unit to create initial creases, ensuring precise folding later.

3. Gluing System – How Is Adhesive Applied?

The gluing system ensures strong bonding and includes:

Glue Tank – Stores adhesive (hot melt, PVA, or cold glue).

Glue Applicator – Precisely dispenses glue on flaps or joints.

Drying System – Speeds up adhesive setting for faster production.

4. Folding Section – How Are Boxes Formed?

This is the heart of the machine, where sheets are folded into their final shape. Different folding methods include:

Crash Lock Folding – For rigid, self-locking boxes.

Straight-Line Folding – For simple carton designs.

Multi-Corner Folding – For complex packaging structures.

5. Pressing & Delivery – How Are Finished Boxes Handled?

After folding, the boxes are pressed to strengthen the bond and then conveyed to the output. Some machines include automatic stacking and counting for organized production.

Folder gluers consist of key components like feeding, pre-folding, gluing, and folding systems, and offer features such as high-speed operation, automatic adjustments, and versatile gluing options for efficient packaging production.

What Features Should You Look for in a Folder Gluer?

1. How Fast Can It Operate?

Modern folder gluers can process thousands of cartons per hour, making them ideal for high-volume production.

2. Can It Handle Different Box Sizes Easily?

Quick-Change Tooling – Reduces downtime when switching between jobs.

PLC Control System – Stores settings for different box designs.

3. What Types of Glue Can It Use?

Cold Glue – Economical for standard packaging.

Hot Melt Glue – Faster drying, perfect for high-speed lines.

4. How Precise Is the Folding?

Laser/Sensor Alignment – Ensures perfect folding accuracy.

Adjustable Folding Plates – Accommodates varying material thicknesses.

5. Can It Integrate with Other Machines?

Many folder gluers can connect with die-cutters, printers, or automated packing systems for a seamless workflow.

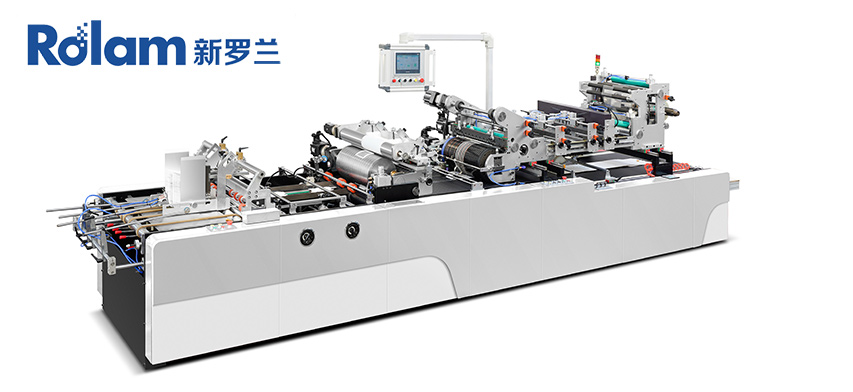

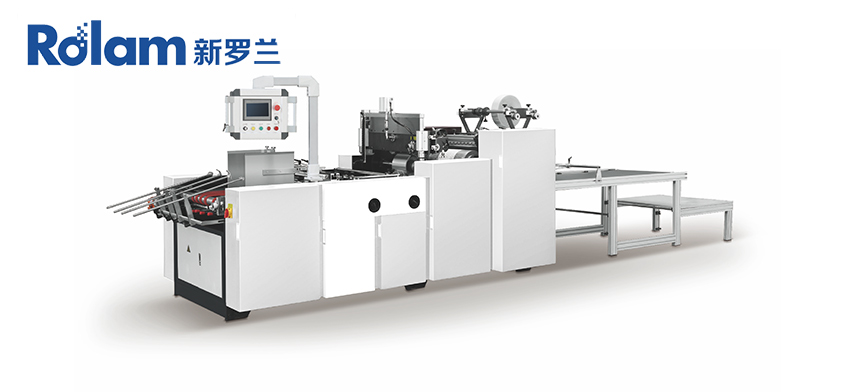

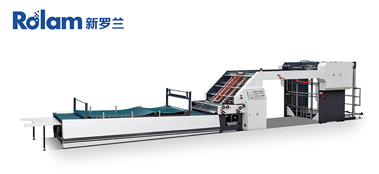

What are the key components and features of Rolam folder gluers?

Key components and features of Rolam folder gluers include:

Adjustable feeding belts with air suction capabilities for smooth operation.

Precise pre-folding and crash lock bottom sections for accurate folding.

Aligner and lower gluing tanks designed for precise box alignment and efficient gluing.

Conveyor systems with adjustable belts and electronic counting devices for streamlined production.

Spraying systems and trombone sections to cater to additional processing requirements.

Conclusion: Is a Folder Gluer Right for Your Business?

Understanding the key components—feeding, pre-folding, gluing, folding, and pressing—along with advanced features like high-speed operation, automatic adjustments, and versatile gluing options will help you choose the best machine for your needs.

Whether you produce corrugated boxes, food packaging, or pharmaceutical cartons, investing in the right folding gluing machine can boost efficiency, reduce waste, and improve product quality.