Common problems of Flute Laminating Machine and solutions for bubbles, compatibility and productivity

For packaging manufacturers, flute laminating issues—bubbles, material mismatches, slow output—waste resources and delay orders. These issues stem from misaligned settings, not flaws. This article shares practical fixes based on proven machine features.

How to Eliminate Bubbles in Flute Laminating

Bubbles between corrugated board and film cause rework. Most trace to uneven heat, inconsistent pressure, or unstable feeding.

Equipment-Driven Solutions

Quality flute laminating machines address these directly:

Dual-Zone Temperature Control: Separate heating/pressure roller controls. Adjust heat for heat-resistant vs. delicate films to avoid incomplete bonding or shrinkage.

Adaptive Pressure Regulation: Machine tweaks pressure to flute thickness—more for thick boards (full contact), less for thin ones (no damage)—eliminating air gaps.

Real-Time Tension Management: Sensors correct feeding shifts instantly to stop misalignment (a top bubble cause).

Quick Ops Tips

Preheat briefly for consistent roller temp.

Store films in a dry area (moisture weakens adhesion).

Test a small batch at shift start; adjust heat/pressure if needed.

Material Compatibility for Flute Laminating Machine

Mismatched boards/films cause peeling or wrinkles. Match material traits to machine settings.

Flute Board Basics

Thick flutes (A-flute): For heavy-duty packaging—more pressure + longer cooling.

Thin flutes (E-flute): For lightweight retail use—gentle pressure + faster cooling.

Balanced flutes (B/C-flute): For general packaging—moderate settings.

Film Type Matching

Standard films (BOPP): Works with most flutes; moderate heat.

Heat-resistant films (PET): For warm-use packaging (food containers); higher heat.

Flexible films (PE): For moisture-proof packaging; lower heat + rubber pressure roller.

Pre-Production Check

1.Confirm board thickness and film type via labels.

2.Use machine’s parameter suggestions (if available).

3.Test a few sheets; adjust for peeling/wrinkles.

Productivity Optimization for Flute Laminating

Many machines underperform due to avoidable downtime. Machine features + smart ops boost output.

Equipment Features to Cut Downtime

Continuous Feeding: Larger board capacity reduces reload stops.

Quick Changeovers: Tool-less adjustments + saved settings speed up film/flute switches.

Fault Alerts: Early warnings for issues (uneven feeding, temp dips) let you fix fast—no shutdowns.

Ops Tips for Speed

Batch Similar Jobs: Group same-film/flute jobs to cut changeovers.

Regular Maintenance: Weekly roller cleaning/inspections prevent breakdowns.

Train Operators: Teach teams to spot early issues (uneven film, odd noises) and adjust.

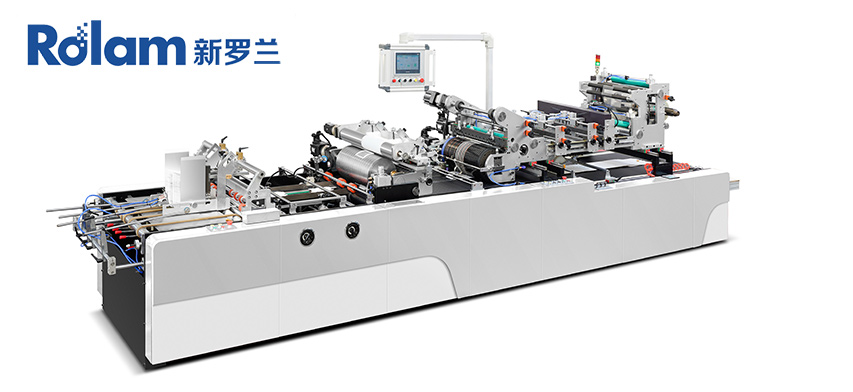

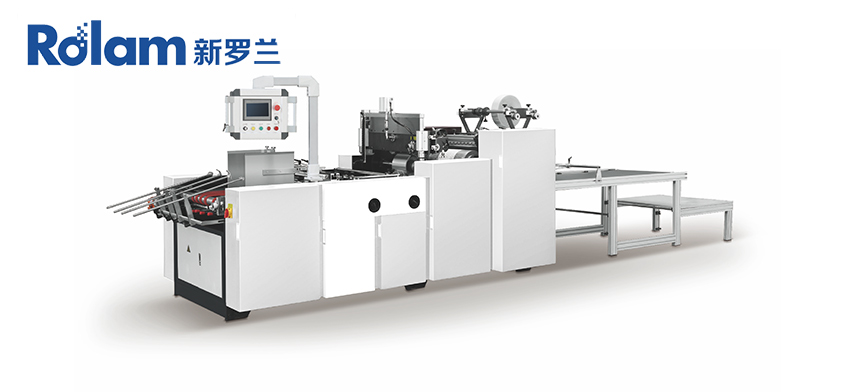

About Rolam Intelligent Technology

With 20 years in packaging equipment, Zhejiang Rolam leads in precision automation. Its 12,000㎡ facility (3,200㎡ machining center) ensures in-house core part precision. Rolam’s flute laminating systems include dual-zone temp control, adaptive pressure, and tension management. It holds CE certification, partners with Rexroth/NSK/Schneider, and offers 24/7 support, 1-year warranty, and on-site training. It designs custom solutions for bubbles, compatibility, or productivity issues.

Conclusion

Flute laminating machine problems are solvable by aligning settings to materials, using efficiency features and performing basic maintenance, and you can partner with Rolam for equipment that solves real challenges or contact Rolam’s team for personalized help.