Get In Touch

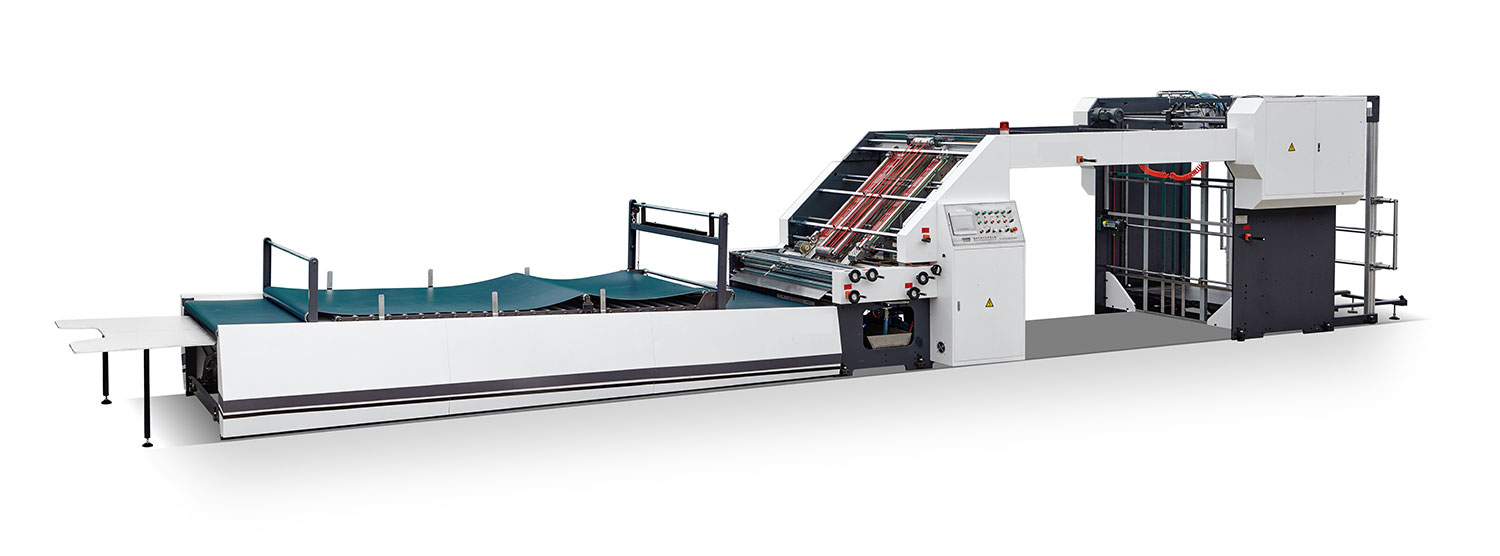

Max Speed 12000sph

One-key Commission 20s Completion

Cardboard To Corrugated Paper & Cardboard To Cardboard

Servo Compensation Positioning

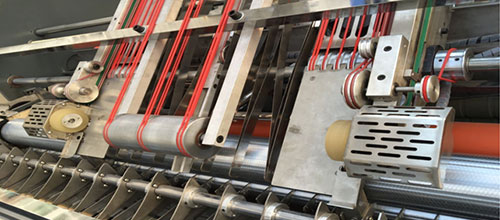

Top Sheet Leet And Right All Course Correction

Top sheet feeding mechanismequipped with high speed auto dedicated feeder, |

|

|

|

Bottom paper feedingUse imported Servo motor electric controlling system, |

Positioning SystemUsing groups of photoelectric sensing bottom |

|

|

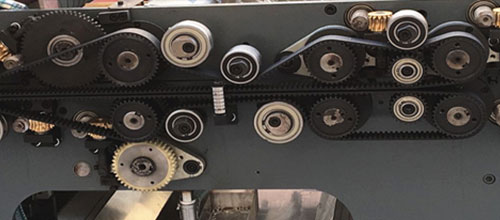

Transmission PartImported double toothed synchronous belt drive, |

Glue rollerStainless steel roller, never rust, after narrowly grinding, |

|

|

|

Electrical systemDesigned in the accordance with European CE requirement, |

Pre-stack sectionpre-stack pile of paper under the condition of non-stop, |

|

|

Flip flop systemStacking the laminated sheets based on the |

|

model |

YB-1450H |

YB-1650H |

|

Max sheet size |

1450×1450mm |

1650×1650mm |

|

Min sheet size |

400×400mm |

400×400mm |

|

Top paper thickness |

120-500g |

120-500g |

|

Precision for front and back |

±1mm |

±1mm |

|

Air Consumption |

0.2m3/min |

0.2m3/min |

|

Overall |

15.5×2.4×2.4M |

15.7×2.6×2.4M |

|

Machine power |

22KW |

25KW |

|

Glue Application |

White glue, Starch glue |

|

|

Bottom paper |

A、B、C、E、F Corrugated paper Four Layers Corrugated paper: AB/BB/BC/EE Cardboard paper is above the 300GSM |

|

If you have any enquiry about quotation or cooperation, please feel free to email us every@gaokemachine.com or use thefollowing enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products

Significant global service network coverage

State-of-the-art machining centers

Exceptional precision Experienced team

Expertise in assembly and design

Machines are available with customization options

Efficient installation and maintenance services

Remote troubleshooting support

Online consultation available 24/7

The packaging industry is evolving fast. As production lines demand higher speed, accuracy, and consistency, smart automation has become the driving force in modern ...

Many people rely on Film Laminators to protect or enhance paper products—from packaging boxes to printed materials—but few know the simple yet key steps that make la...

A flute laminating machine is a workhorse for packaging production, but its performance relies heavily on proper upkeep. Many users overlook routine maintenance, lea...

GET A QUOTE