Get In Touch

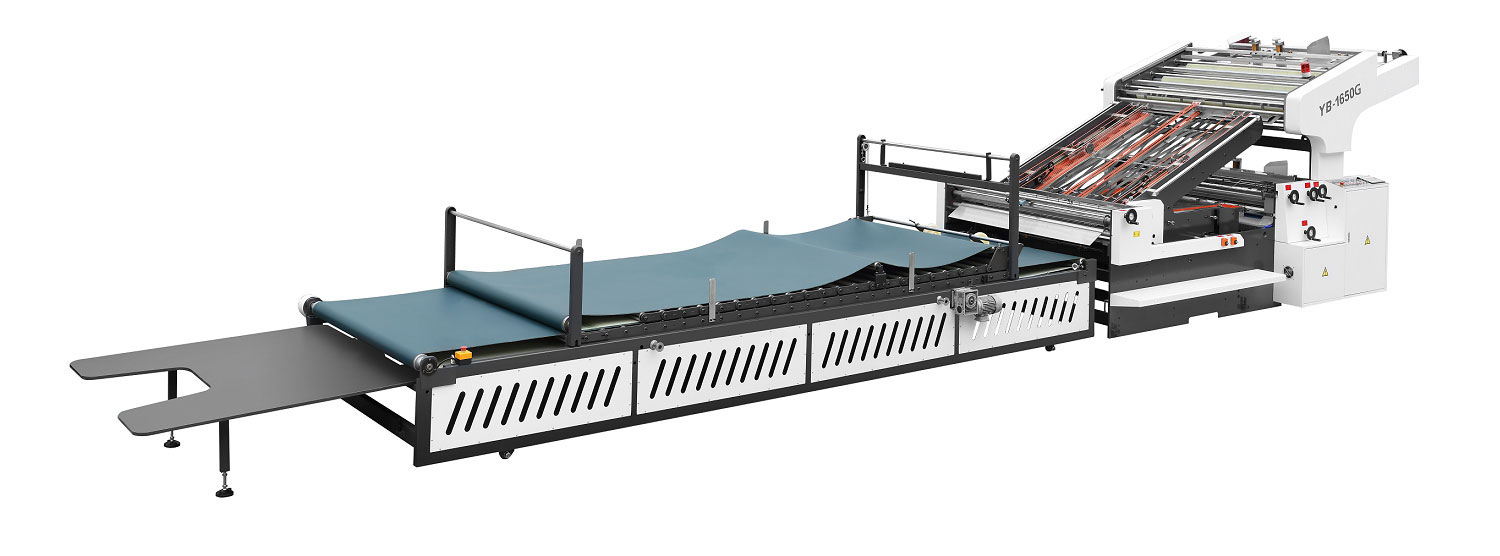

Max speed 10000sheet/hour

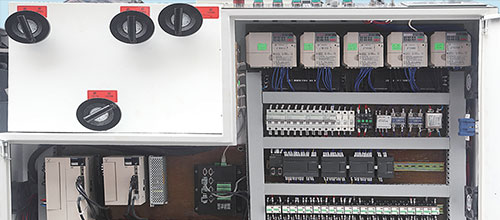

The most advanced electrical control system

Full accomplishment of intelligence and automation

Automatic adjustment when changing sheet size

Curve velocity assures the high accuracy

The newest technology of intermittent registration

Top and bottom sheet automatic tracing

Bottom sheet left and right whole course correction

Top sheet left and right whole course correction

Intelligent detection of sheet length

Intelligent error display and alarm system

Intelligent glue supplying and recycling system

Intelligent cleaning and water circulation system

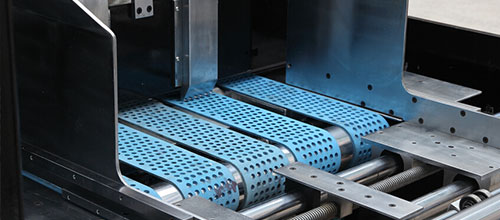

Bottom sheet bend and pressurize device

Bottom sheet suction power adjustment device

US MAC component opens and closes suction

Stainless steel gluing cylinder

Anti glue swing device

|

Model |

YB-1650G Corrugation to Corrugation |

|

Max. sheet size |

1650X1450mm |

|

Min. sheet size |

550X550mm |

|

Max Speed |

100m/min |

|

Accuracy |

±1.5mm |

|

Overall |

10X2.4X2.3M |

|

Machine weight |

8000kg |

|

Machine power |

22KW/380V |

|

Top paper |

A/B/C/E/F Two layers corrugated paper |

|

Bottom paper |

A/B/C/E/F Two layers corrugated paper |

|

Top and Bottom paper feeding Use imported Servo motor electric controlling system, |

|

|

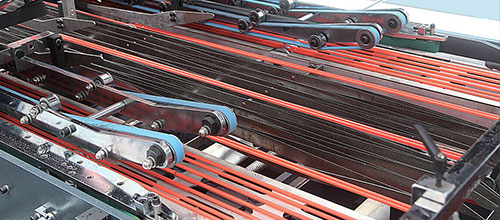

Top Sheet Feeding Mechanism Servo control of the intermittent fixed position, in the process of positioning, positioning gauge work as "start – speed up – trackingspeed reduction-stop" curve speed run, make sure positioning more accurate. |

| Side Positioning Left and right side synchronous block complete the accurate positioning, both top sheet and bottom paper are equipped with accurate positioning device on left and right. |

|

|

Glue Roller Stainless steel roller, never rust, after narrowly grinding, guaranteed the minimum amount glue coated evenly. Down roller be cleaned by water roller. |

| Transmission With imported double teeth belt drive and Switzerland ROSTA tension device ensure the drive accurate, stable and low noisy. |

|

|

Electrical System Designed in the accordance with European CE requirement, ensure machine stability, high efficiency and low failure. Using man-machine interface and PLC combination, display all the information, such as warning, error detect, failures, and operating speed, etc on the screen at a glance. |

If you have any enquiry about quotation or cooperation, please feel free to email us every@gaokemachine.com or use thefollowing enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products

Significant global service network coverage

State-of-the-art machining centers

Exceptional precision Experienced team

Expertise in assembly and design

Machines are available with customization options

Efficient installation and maintenance services

Remote troubleshooting support

Online consultation available 24/7

The packaging industry is evolving fast. As production lines demand higher speed, accuracy, and consistency, smart automation has become the driving force in modern ...

Many people rely on Film Laminators to protect or enhance paper products—from packaging boxes to printed materials—but few know the simple yet key steps that make la...

A flute laminating machine is a workhorse for packaging production, but its performance relies heavily on proper upkeep. Many users overlook routine maintenance, lea...

GET A QUOTE