Get In Touch

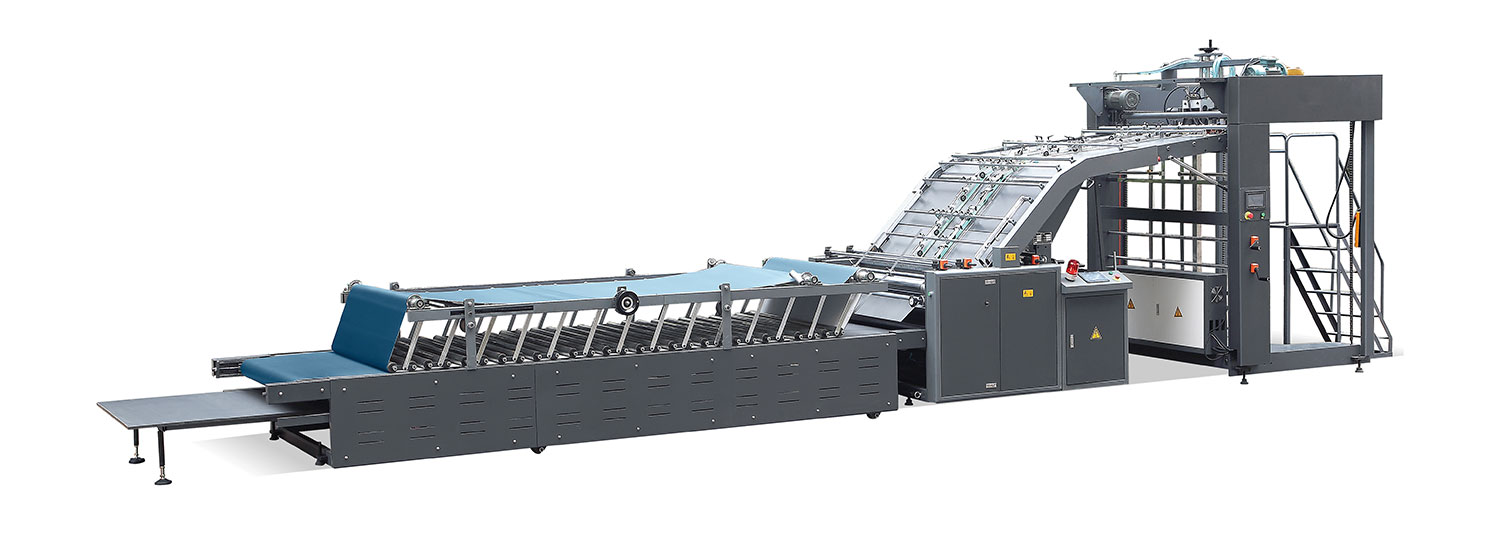

Unique front gauge positioning system, positioning accuracy, the bottom paper never exceed, top paper exceed can be adjusted.

Equipped with high precision and high speed feeder system, strengthening paper feeding device, feeding smoothly.

Bottom paper using suction automatic feeding, according to main machine running speed, automatic tracking continuity.

Inported electrical components ensure the stability of the electrical system. PLC tracking technology, automatic fault alarm.

Fully automatic glue suplement system, can automatically replenish the loss of the glue, and cooperated, with the glue recycling.

The scientific design of the roller line speed make sure the uniformity of the gule, at the same time to avoid glue being threw off during high speed running

Floating type movable pressing belt, ensure that the laminated paper will not be crushed and also ensure the sheets smooth straight.

Independent water tank control cycle, ensure the bottom paper back dry and clean, and cleaning glue rollers, glue collecting tank, back glue tank at the same time.

Single side adjustment of the pressure roller, and equipped with a pressure gauge, with the record of the data , easy adjustment when change the size of bottom paper.

Manual /Auto two function universal model

Long working, short working

Quality paper, bad sheets

Flute laminating, gray board laminating

Small quantity working -- Manual Feeding

Big quantity working -- Feeding Feeding

Curve top sheets – Manual Feeding

|

Model |

YB-1300D |

YB-1450D |

YB-1650D |

|

Max Sheet |

1300×1250mm |

1450×1250mm |

1650×1450mm |

|

Min Sheet |

400×400mm |

400×400mm |

400×400mm |

|

Top Paper Thickness |

150g-600g |

150g-600g |

150g-600g |

|

Max Speed |

6000 Sheets/hour |

6000 Sheets/hour |

6000 Sheets/hour |

|

Fitting Precision |

±1.5mm |

±1.5mm |

±1.5mm |

|

Measurement |

10×2×2.4M |

10×2.2×2.4M |

10×2.4×2.4M |

|

Machine Weight |

4500kg |

5000kg |

5500kg |

|

Machine Power |

10KW/380V |

11KW/380V |

12KW/380V |

|

Bottom Paper Thickness |

A、B、C、E、F、AB、BB、BC、EECorrugated paper),(Industrial paperboard) |

||

If you have any enquiry about quotation or cooperation, please feel free to email us every@gaokemachine.com or use thefollowing enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products

Significant global service network coverage

State-of-the-art machining centers

Exceptional precision Experienced team

Expertise in assembly and design

Machines are available with customization options

Efficient installation and maintenance services

Remote troubleshooting support

Online consultation available 24/7

The packaging industry is evolving fast. As production lines demand higher speed, accuracy, and consistency, smart automation has become the driving force in modern ...

Many people rely on Film Laminators to protect or enhance paper products—from packaging boxes to printed materials—but few know the simple yet key steps that make la...

A flute laminating machine is a workhorse for packaging production, but its performance relies heavily on proper upkeep. Many users overlook routine maintenance, lea...

GET A QUOTE