Get In Touch

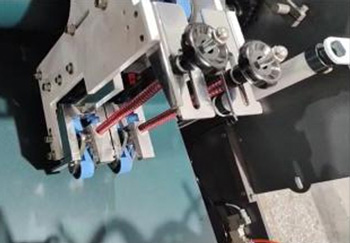

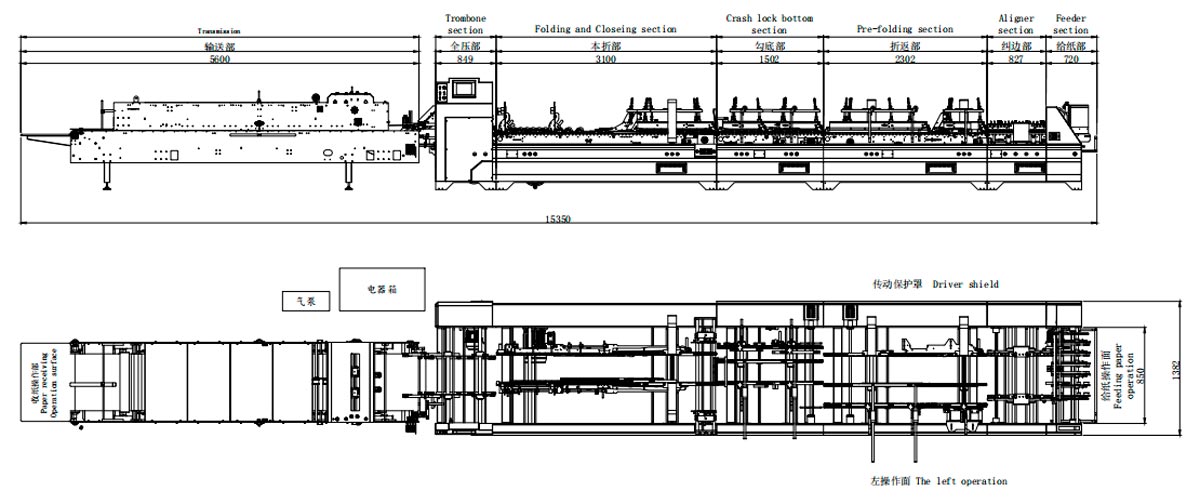

New universal multi-function section with integrated bump & turn allows to turn cartons 90º and its alignment. Pre-breakers device by outer belts on both sides. New drives technologies, extra length crash lock bottom section. Extra folding & closing section with collapsible central carrier, able to produce complex carton structures, straight line, lock bottom, 4 & 6 corner cartons and more. GK-H series machine has emerged with high automation and fully functional, which help box manufacturer to make the best use of paper material and improve efficiency of box producing.

we persist on innovative and High-performance. It help us to provide the most competitive gluing and folding equipment for all the customers!

|

MODEL |

GK-H650-BL |

GK-H800-BL |

GK-H1100-BL |

|

Paper material |

Cardboard 210-800gsm,A/B/E Flute |

||

|

Max.Speed |

400m/min |

||

|

Max.thickness of folded box |

12mm |

12mm |

12mm |

|

Way of folding |

Fold 1 and fold 3 are 180°and 165° |

||

|

Power supply |

3P 380V 50HZ |

||

|

Blank width |

650mm |

800mm |

1100mm |

|

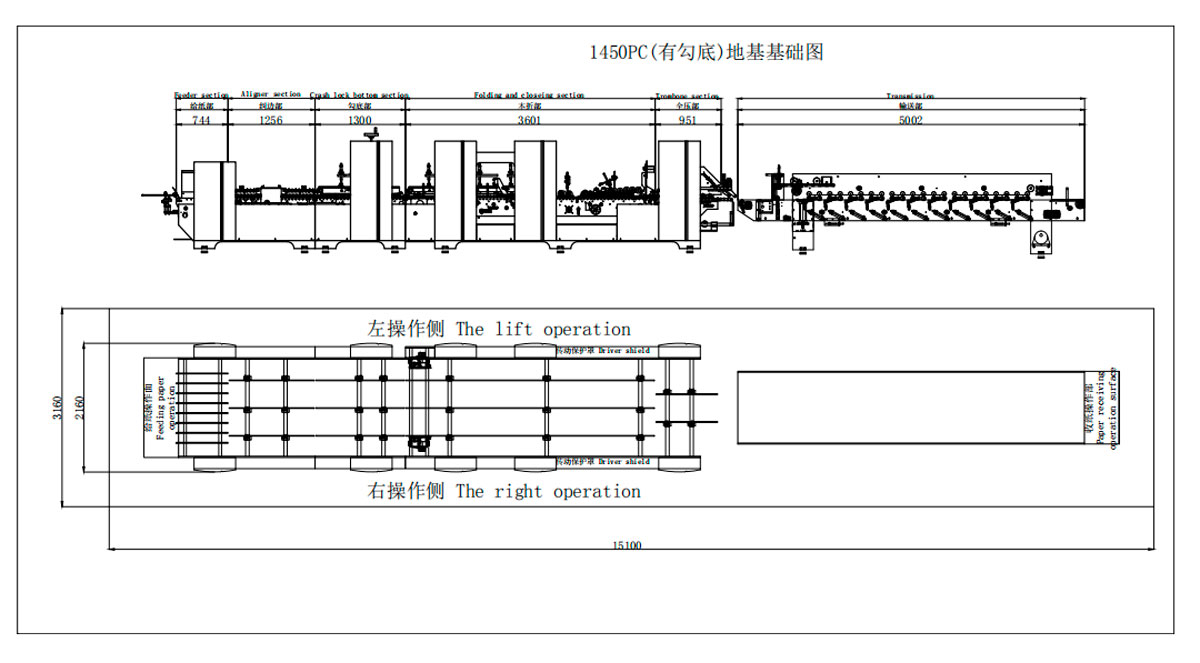

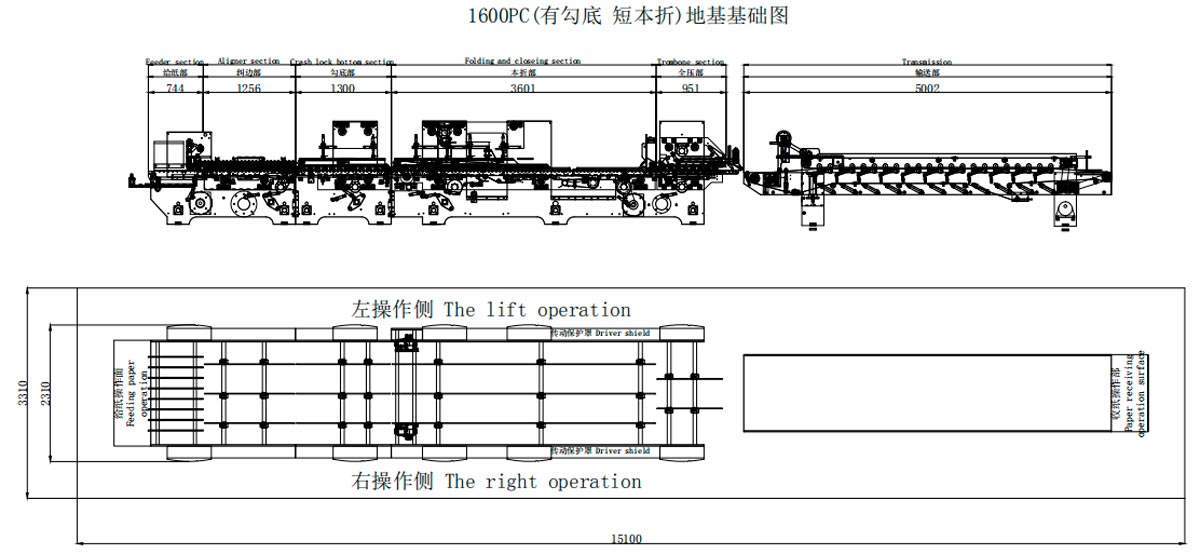

Length x Width x Height |

13x1.3x1.3m |

15x1.5x1.3m |

15x1.8x1.3m |

|

Net Weight |

5T |

6T |

7T |

|

Total power |

28.6kw |

31.18kw |

31.18kw |

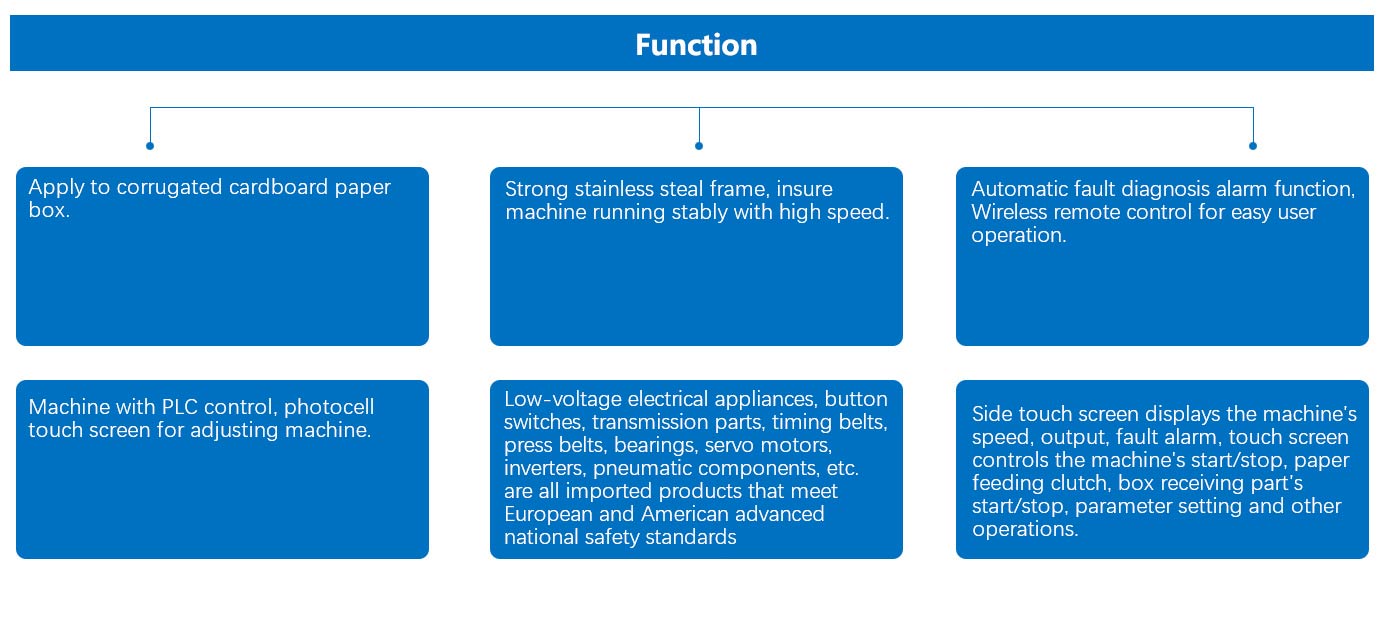

Paper Feeding Section1. The feed part is driven by variable frequency motor |

|

Aligner sectionThe paper board sent from feeder section will be corrected |

|

Pre-folding sectionSpecial first folding line pre-fold 180°. |

|

Crash lock bottom sectionCompete set of crash lock bottom device makes |

-1647.jpg) |

Lower gluing tank1.Lower gluing tank is 2L. |

|

|

Folding and closing1.Collapsible central carrier by pneumatic system, |

|

Trombone section1.Up and down belt can be adjusted separately. |

|

TransmissionEquipped with special additional sponge belt |

|

Box SquaringFull press section continuously and |

|

Spraying SystemEquipped with three guns, |

|

Straight Line Box |

|

|||

|

Model |

GK-H650-BL |

GK-H800-BL |

GK-H1100-BL |

|

|

Way of folding |

Two carriers |

Two carriers |

Two /three carriers |

|

|

B+C+D+E |

130-650 |

130-800 |

130/280-1100 |

|

|

C+D |

65 |

65 |

65/140 |

|

|

E(Min) |

30 |

30 |

30 |

|

|

E(Max) |

500 |

500 |

500 |

|

|

F |

70-800 |

70-800 |

70-800 |

|

|

G(Max) |

800 |

800 |

800 |

|

|

Prefolding |

||||

|

D+E(Max) |

300 |

300 |

300 |

|

|

G(Max) |

500 |

500 |

500 |

|

(Final folding by one carrier:B+C+D+E min feeding width 75mm)

|

Crash Lock Bottom Box |

|

|||

|

Model |

GK-H650-BL |

GK-H800-BL |

GK-H1100-BL |

|

|

Way of folding |

Two carriers |

Two carriers |

Two /three carriers |

|

|

B+C+D+E |

130-650 |

130-800 |

130/280-1100 |

|

|

C+D |

65 |

65 |

65/140 |

|

|

E(Min) |

30 |

30 |

30 |

|

|

E(Max) |

500 |

500 |

500 |

|

|

F |

70-800 |

70-800 |

70-800 |

|

|

G(Max) |

800 |

800 |

800 |

|

|

H(Min) |

25 |

25 |

25 |

|

|

L |

30-100 |

30-100 |

30-100 |

|

GK-H650-BL

GK-H800-BL

GK-H1100-BL

If you have any enquiry about quotation or cooperation, please feel free to email us every@gaokemachine.com or use thefollowing enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products

Significant global service network coverage

State-of-the-art machining centers

Exceptional precision Experienced team

Expertise in assembly and design

Machines are available with customization options

Efficient installation and maintenance services

Remote troubleshooting support

Online consultation available 24/7

The packaging industry is evolving fast. As production lines demand higher speed, accuracy, and consistency, smart automation has become the driving force in modern ...

Many people rely on Film Laminators to protect or enhance paper products—from packaging boxes to printed materials—but few know the simple yet key steps that make la...

A flute laminating machine is a workhorse for packaging production, but its performance relies heavily on proper upkeep. Many users overlook routine maintenance, lea...

GET A QUOTE